Nobody expected that real objects could be printed using printers; as baffling as that thought is, it is now a very real possibility! Let’s see what all this amazing technology entails.

Technology is advancing and evolving at such a rapid pace today that sometimes even we are caught by surprise by some of the innovations we hear about. This rapid evolvement has enabled faster change and progress which is another good thing. We are constantly learning and unlearning things, rules and how the world works to bring about new advancements in technology and one of these advancements is 3D printing technology. 3D printing is a key trend in the technology world and is used in the formulation of prototypes. No one really thought we’d be able to print objects directly from a printer – real objects – but here we are! It is in our reality and this innovation is here to stay. In many industries, this technique has been experimented with a lot, the major one being the healthcare industry. If you keep up with the latest happenings in the tech industry, you would have heard that using 3D printing, doctors and scientists have successfully saved patients, by using this technology to print organs required by them. It definitely seems like this technique has a lot of upsides to it. Let’s check out 3D printing in a little more detail and see what the hype is about.

An innovation that seems like it’s here to stay, 3D printing technology has advanced by leaps and bounds.

TYPES OF 3D PRINTING

Various manufacturing technologies come under 3D printing. These technologies build parts layer-by-layer and each is different in the way they form the plastic and metal parts. But there are also various types of 3D printing:

1. Stereolithography (SLA)

2. Selective Laser Sintering (SLS)

3. Fused Deposition Modeling (FDM)

4. Digital Light Process (DLP)

5. Multi Jet Fusion (MJF)

6. PolyJet

7. Direct Metal Laser Sintering (DMLS)

8. Electron Beam Melting (EBM)

While making use of this technology, it is important to select the right 3D printing process for your needs, by considering the strengths and weakness of each in respect to your product development needs.

3D printing accords designers the ability to quickly turn concepts into prototypes or 3D models.

HOW DOES IT WORK

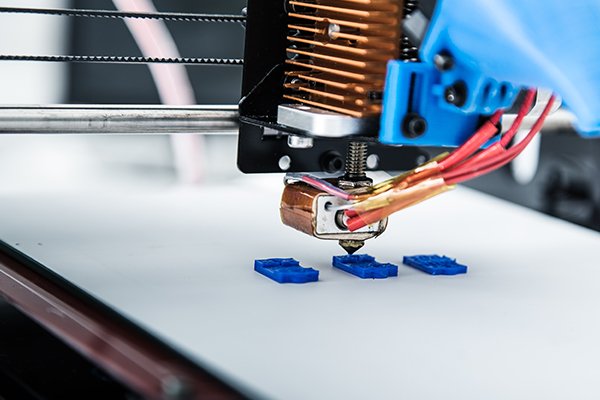

In the most basic terms, 3D printing is a manufacturing process. During this process, material is laid down layer by layer which then forms into a 4-dimensional object. The object gets built from scratch and 3D printers make use of a variety of materials to create these objects. They also possess the ability to turn digital files into physical objects. These printers use a variety of technologies and the most commonly used technology is that of FDM or fused deposition modelling. It is also known as FF or fused filament fabrication. In this, a filament is melted and then deposited through a heated extrusion nozzle in layers.

This is just one technology. Another technology used is stereolithography. In this, a UV light gets shined into a vat of ultraviolet-sensitive photopolymer and traces the object on the surface. The polymer then solidifies as the beam touches it and the object gets printed layer by layer by the beam from the instructions in the CAD or CAM file it’s working from. Another is DLP or digital light projector 3D printing where a liquid polymer is exposed to light from a digital light processing projector. The polymer hardens layer by layer till the object gets built and the remaining polymer liquid is then drained off.

These are just a few techniques. Now, let’s see some uses for this technique and its applications in the real world.

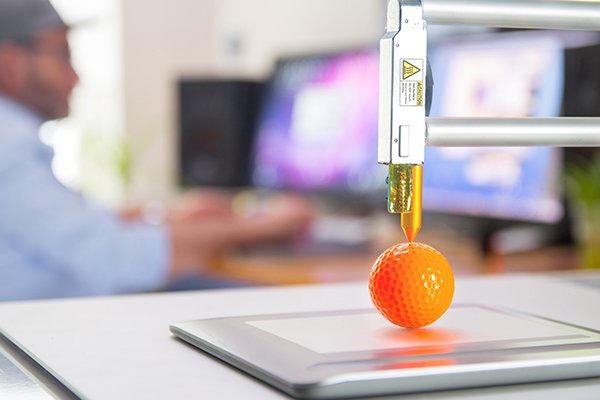

In 3D printing, material is laid down layer by layer which then forms into a 4-dimensional object.

BENEFITS OF 3D PRINTING

3D printing accords designers the ability to quickly turn concepts into prototypes or 3D models which makes it possible to also implement quick design changes. Manufacturers are able to print products on demand rather than waiting until they have a stock of products ready which improves inventory management and reduces the need for warehouse space. Another advantage is that people residing in remote areas can manufacture objects that would otherwise be hard for them to obtain. When looking at this technology from a practical standpoint, 3D printing helps save money and material and reduces wastage of raw material. It is convenient, and it is easy. This is why 3D printing is becoming the hot new trend and it is definitely here to stay.

You can use 3D printers to make shoe designs, furniture, wax castings for jewellery, tools, tripods, gifts,

etc.

USES OF 3D PRINTING

3D printers are being used by designers to quickly and rapidly create models and prototypes but that’s not all. The technology is also used to make final products too. 3D printers can make a wide variety of objects. You can use 3D printers to make shoe designs, furniture, wax castings for jewellery, tools, tripods, gifts, etc. Novelty items and toys can also be created using 3D printers. Automotive and aviation industries also use 3D printers to print parts. And artists can make use of 3D printers to create sculptures, etc. Architects fabricate project models and archaeologists also make use of it to reconstruct models of fragile artefacts if needed.